Authored by Daniel Patrascu via autoevolution,

Thanks to the many ongoing projects in this field, we’re used by now to seeing humanoid robots performing all sorts of impressive, almost human-like tasks and movements. But it’s not until you see one performing something as mundane as moving things from one box to another, or arranging stuff on a shelf, that you realize just how far things have gone.

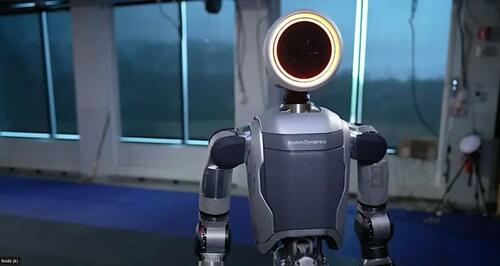

Boston Dynamics, one of the most important names in robotics on this planet, has been working on a humanoid robot ever since 2013. It calls it the Atlas, and it April last year the most recent version of the machine made its way under the spotlight.

As it presents itself today, the Atlas is made of titanium and aluminum 3D printed parts and stands five feet (1.5 meters) tall. Tipping the scales at 196 pounds (89 kg), it has hands, legs, and a head that move thanks to no less than 28 electrically powered joints.

The previous versions were powered by hydraulics, and that kind of limited the range of motions the robot was able to perform, but also its strength, to some degree. Now that the switch to electricity has been made, the sky is the limit.

Like all other robots of its kind, the Atlas can lift and maneuver loads, including irregular objects, and can navigate unstructured, difficult terrain, without any prior knowledge of it. And it looks amazing doing all of that, thanks to the light ring head propped on the torso.

But a robot, no matter how spectacular its body is, is as good and effective as the software that powers it. In its current form, the Atlas uses the same software that powered the previous versions, but there were plans to deploy the Orbit, a solution that already powers the Spot dog-like robot.

In the fall of last year Japanese carmaker Toyota got involved in the Atlas project. Through the Toyota Research Institute (TRI), the company got in bed with Boston Dynamics (which, by the way, is owned by South Korean carmaker Hyundai) to gift the Atlas with one of its Large Behavior Models (LBM) solutions.

The basic idea about LBM is that it can be used to improve the robot’s dexterous manipulation skills, allowing it to perform a multitude of tasks, including simultaneously. Above all, such a system allows robots to gain skills by simply watching demonstrations from humans, requiring no complex code to be written.

It’s been months since the partnership between Boston Dynamics and TRI was announced, and to be fair, I kind of forgot all about it. Then the two partners published a stunning video of the Atlas (attached below this text) performing all sorts of tasks in a room somewhere, all while humans tried to play tricks on it.

The Atlas, powered by the TRI LBM, is seen at first repeatedly crouching to pick up some what appear to be the body parts of its sibling robot, the Spot, from inside a box. It then rises up and deposits them in another container.

It sounds like a pretty simple task, and it is, at least for a human. Present-day robots find it extremely difficult to coordinate hands and legs to such a degree, combining object manipulation with locomotion, especially when nearby humans “interject unexpected physical challenges mid-task.”

What it means is that, from time to time, a human closes the lids of the box that contains Spot parts using a hockey stick, or simply pulls the box away from Atlas. The robot doesn’t seem to mind, and patiently reopens the box or pulls it back close to it to continue its work.

The second part of the video shows the Atlas picking up Spot components from a table and depositing them on nearby shelves, including in boxes. In doing so, the robot shows real skill in performing packing, sorting, and organizing tasks.

According to the two partners in this research, the incredible coordination of the robot’s actions is owed to the fact that a single LBM controls the entire machine, “treating the hands and the feet almost identically.”

It’s unclear what the next step in the project is, but we now hope the next update on the Atlas will come our way much sooner than a few months.

Just like the Spot, the Atlas was imagined by Boston Dynamics as a tool to be used in industrial settings. Among the first companies to adopt it for real-world applications is Hyundai, which plans to incorporate it into its carmaking operations. When will that happen is anybody’s guess…

The Atlas is not the only humanoid robot currently in the works, and not even the only one that will be deployed in the automotive industry. The Sanctuary AI Phoenix has already been tested on the floor of the Canadian Tire Corporation (CTC) and European auto supplier Magna, the Apptronik Apollo is expected to work for Mercedes-Benz, the Figure 02 is on team BMW, and the Tesla Optimus, well, you know where that one is going…

h/t Capital.news

Tyler Durden

Fri, 08/22/2025 – 20:05

Click this link for the original source of this article.

Author: Tyler Durden

This content is courtesy of, and owned and copyrighted by, https://zerohedge.com and its author. This content is made available by use of the public RSS feed offered by the host site and is used for educational purposes only. If you are the author or represent the host site and would like this content removed now and in the future, please contact USSANews.com using the email address in the Contact page found in the website menu.